Your Trusted Source for PVC Foam Board, PVC Trim & Moulding, Rigid PVC Sheet, Acrylic, and More

- 📧sale@boardwaybuilding.com💬86 138 2826 6785

How to cut pvc foam sheet? CNC or laser cutting?

Before we answer the question, let's disucss what is the heat distortion and melting temperatures of PVC sheet?

The heat stability of raw PVC is very poor, so the addition of a heat stabilizer during the process is necessary in order to ensure the product's properties.

Traditional product PVC has a maximum operating temperature around 60 °C (140 °F) when heat distortion begins to occur.Melting temperatures range from 100 °C (212 °F) to 260 °C (500 °F) depending upon manufacture additives to the PVC.

For CNC machine, during cutting PVC foam sheet, which will produce low heat between the cutting tool and pvc sheet, which is about about 20 °C (42 °F), while cutting other material such as HPL, the heat is higher, about 40°C (84°F).

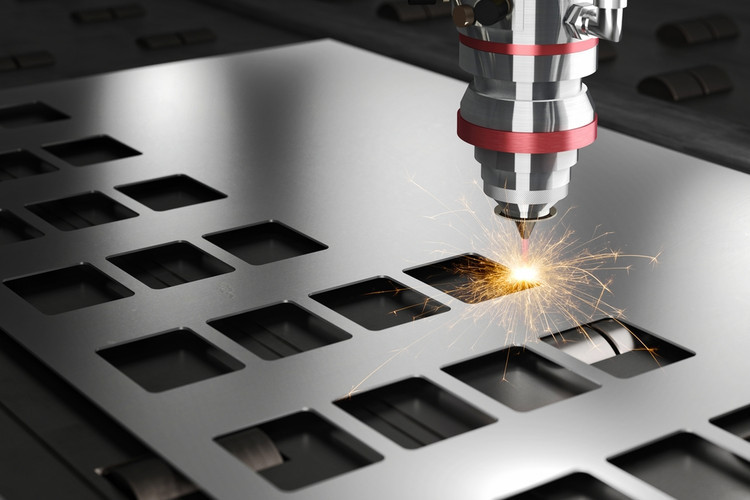

For laser cutting, depend on the material and power factor, 1. for cutting no metel it is about 800-1000 °C (1696 -2120°F) . 2. cutting metel is about 2000 °C (4240°F).

Conclusion

PVC board is suitable to processing with CNC machine, not by laser cutting. The high temperature brought by laser cutting will cause the PVC boardto burn and turn yellow, or even soften and deform.

Here is a list for your reference:

Material suitable to cut by CNC machine: PVC sheet, including pvc foam sheet and PVC rigid sheet, WPC foam sheet, cement board, HPL panel, aluminium panel, PP corrugated sheet (PP correx sheet), solid PP sheet, PE sheet and ABS.

Mateiral suitable to cut by Laser machine: wood, acrylic sheet, PET sheet, metal.

GET A QUOTE

If you have an idea but you don't know what kind of material to use, which way to process it, please feel free to share your idea with us and we will provide you the best solution! Email us at sale@boardwaybuilding.com

- Tel

- *Title

- *Content

Manufacturing, Wholesale, Custom Processing for Plastic PVC Sheets and Profiles