Manufacturing Process of PVC Foam Board

What Is PVC Foam Board?

PVC foam board, we can know from its name that it is a expanded PVC board.

PVC foam board is basically composed of polyvinyl chloride and other auxiliary materials. During the production process, a large number of bubbles are generated under the action of the foaming agent. PVC sheet expands to a specific width and thickness, and forms a rigid closed-cell foam sheet after cooling.

We have attached a video below to let you see our production process of PVC foam board more intuitively.

More videos about PVC foam board at https://www.boardwaybuilding.com/comm03/Video.htm

1. Preparation of materials

The process of preparing raw materials is also a mathematical process. We need to determine the raw material (polyvinyl chloride) and auxiliary materials according to the production order (a production document that is converted into a Boardway factory production order based on a customer order), and calculate the quantity of each raw materials to be used. The types of auxiliary materials include stabilizers, foaming agents, foaming regulators, lubricants, and fillers.

For PVC foam boards with enhanced performance, such as UV-resistant PVC foam boards, PVC foam boards with flame retardant grade A, or PVC foam boards with enhanced hardness, we will strengthen the performance of PVC foam board by adding reinforcing agents. In addition, if the colored PVC foam board is to be produced, the color masterbatch is one of the materials we need to prepare.

After all the materials required for production are confirmed, we need to mix all the materials in proportion. The proportion of the formula is often different due to different production equipment and different sources of raw materials and auxiliary materials. We can say that a perfect formula is the result of the running-in of skilled technicians and production equipment.

2. Foaming process

After entering the production equipment, the raw material is heated at high temperature and expands uniformly under the comprehensive action of various auxiliary materials.

The foaming of PVC foam board is divided into three processes: cell formation, cell expansion and cell curing.

The foam expansion has a decisive influence on the quality of the PVC foam board, and it is also a determinant of the density. During these three processes, technicians need to control the foam to expand evenly at a gentle rate to prevent overexpansion of cells, collapse of cells, or cells coalescence to form large bubbles.

Attached to the right is a picture of a PVC foam board failing to foam.

Every time the production starts, it must go through such a process of foaming adjustment.

In the initial stage of production, the cell expansion has not yet reached a stable level, causing the surface of the board to gather cells and keep expanding to bubbles.

Before the stable production of PVC foam board, a large amount of waste boards will be generated, resulting in material loss. That's why we set a minimum order quantity (MOQ) for PVC foam board.

The production of colored PVC foam boards requires more process of color adjustment than the production of white boards, so its MOQ is higher.

3. Extrusion and cooling of PVC foam board

We often hear a term called "extruded plastic sheet". The word "extrusion" comes from its production process.

After the raw material melt is extruded from the mouth die, technicians need to control the complete decomposition of the foaming agent from the mouth die to the shaping die. At the same time, it is necessary to use the stabilizer to control the stability of the decomposition process to ensure that the PVC foam board is produced continuously and stably.

PVC foam board with good stability and shaping has smaller dimensional deviation. Lubricants are divided into internal lubricants and external lubricants. Internal lubricants are beneficial for plasticization and fluidity of raw material melts, controlling sheet width and thickness. The external lubricant plays a role in increasing the lubrication when the PVC foam sheet is extruded and improving the surface finish of the sheet.

Finally, the PVC foam board is cooled and formed after passing through 4 sets of shaping dies.

4. Covering with protective film and cut to length

After the PVC foam board is extruded from the shaping dies, the edge material of the board is cut off by the cutter fixed at both ends of the width. In this process, we can cover the board with protective film or not according to customer needs.

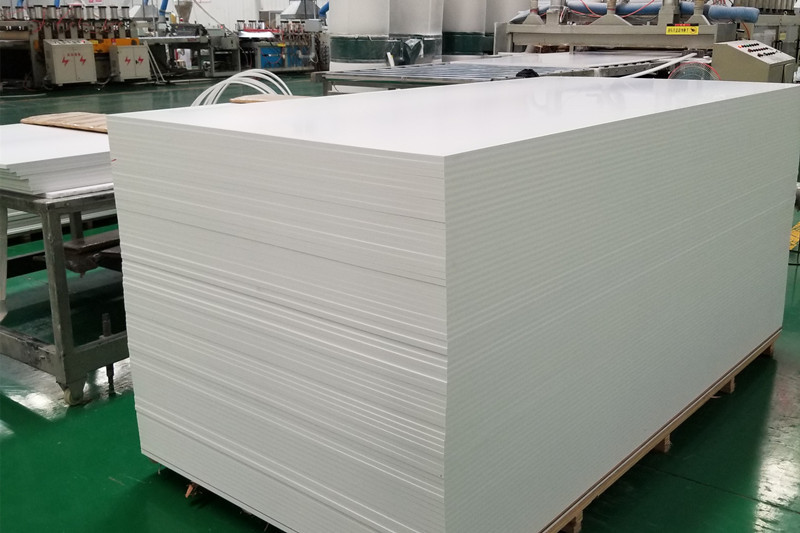

At the end of production line, the PVC foam board is cut to standard length (8 feet) or custom length.

Click to view Boardway Product List

Click to view Boardway Processing Services