How to Test PVC Foam Board?

If you are not very familiar with PVC foam board, then you may have the following doubts:

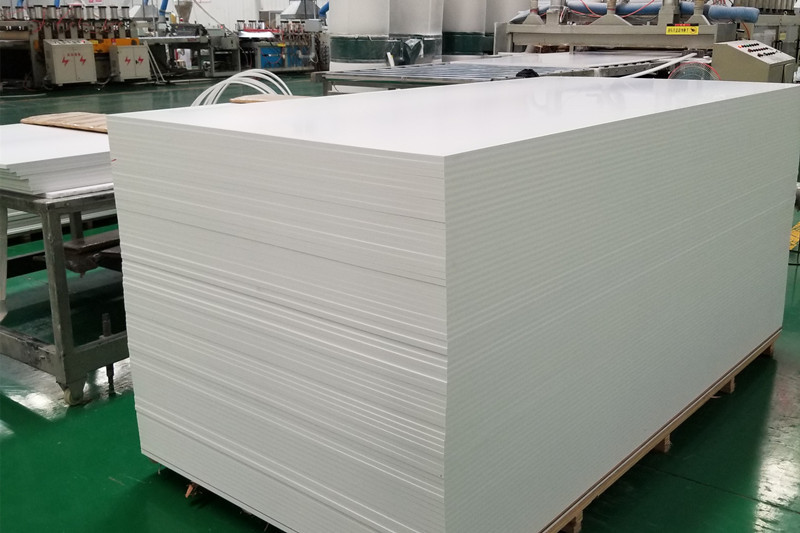

I received the PVC foam board from the supplier, but how do I check whether it is qualified?

This blog shares how Boardway inspects PVC foam boards. We believe that after reading this article, you can test it yourself according to the methods we provide.

How Do We Test PVC Foam Board?

Appearance Inspection

The appearance inspection is to inspect the surface and sides of the PVC foam board by visual inspection.

1) Surface of the board

It is smooth to the touch with no obvious mechanical texture and no scratches.

There is no color difference in surface color. Colored PVC foam boards in particular need to be carefully inspected for changes in color shades.

The surface is free of stains and impurities, no obvious pits and cracks.

2) Sides of the board

The cutting edge is smooth, without obvious serrations.

The cells are fine and uniformly, there are no obvious large cells.

There is not a lot of powder fall off after touching.

Specification Tesing

Specification testing refers to testing whether the length, width, diagonal deviation, thickness, warpage, density and hardness of the PVC foam board are within the tolerance.

The measuring tools we use are tapeline with an accuracy of 1mm, ruler with an accuracy of 1mm, vernier caliper, electronic scale, Shore durometer. The following measurement data is based on the standard size of PVC foam board (1220mm x 2440mm) as an example, the tolerance range is from the Boardway factory's internal inspection standard.

(1) Length: measure with a tapeline.

(2) Width: measure with a tapeline.

(3) Diagonal deviation: measure the lengths of two diagonals with a tapeline, and calculate their difference.

(4) Thickness: measure with a vernier caliper. Measure at intervals of 200mm in the width direction, and take the maximum and minimum values.

(5) Warpage: place the pvc foam board on an absolute plane. Use a ruler to measure the height difference between the surface of the board and the horizontal plane, and take the maximum and minimum values. Take the difference between the maximum and minimum value as the warpage.

(6) Density formula: density (g/cm3) = weight (g)/length × width × thickness (cm).

(7) Hardness: Use a Shore durometer to measure the hardness on the surface of the board.

|

ITEM

|

TOLERANCE |

|

|

Length

|

≥ 0mm

|

|

|

Width

|

≥ 0mm

|

|

|

Diagonal Deviation

|

<10mm

|

|

Thickness (t) | 1mm ≤ t ≤ 5mm | ± 0.15mm |

5mm < t ≤ 20mm | ± 0.2mm | |

20mm < t ≤ 25mm | ± 0.3mm | |

Warpage | t ≤ 5mm | ≤ 10mm |

t > 5mm | ≤ 5mm | |

Density | ± 0.02g/cm3 | |

Performance Testing

Appearance inspection and specification testing can be directly obtained by testing the exterior of the PVC foam board with the help of some simple tools. The performance of PVC foam board, such as water absorption, burning performance, UV resistance performance, bending strength and other physical and chemical properties, requires the help of more complex professional testing equipment, and can be tested in a certain environment.

For performance testing, we need to contact the laboratory and inform them of the products and test items we want to test. And prepare a certain number of small samples of PVC foam board to the laboratory. Usually different test items require different specifications and quantities of samples, and we can prepare them according to the requirements of the laboratory.

The lab test usually takes 20 to 30 days. After the tests are completed, the lab will issue a product test report to us.

Click to view Boardway Product List

Click to view Boardway Processing Services