What is PVC Foam Board Laminate? Share from Manufacturer

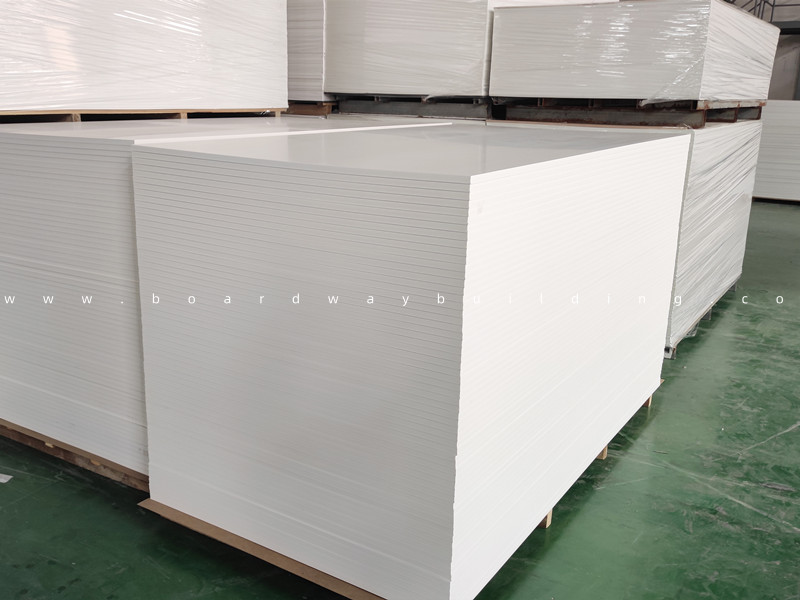

As a common and widely used plastic sheet, PVC foam board has many advantages such as light weight, waterproof and mildew proof, flame retardant, easy processing, non-toxic and formaldehyde-free, etc. It is often used in the manufacture of kitchen cabinets, bathroom vanities, Interior decoration and boat furniture etc. However, PVC foam board is plain and patternless, which cannot be applied to all scenarios and meet the different preferences of consumers. Therefore, the PVC foam board laminates are designed.

More videos about PVC foam board at https://www.boardwaybuilding.com/comm03/Video.htm

What is PVC foam board laminate?

PVC foam board laminate refers to a thin decorative material that is laminated on one or both sides of PVC foam board. It consists of three parts, substrate, glue and decorative surface material.

Substrate

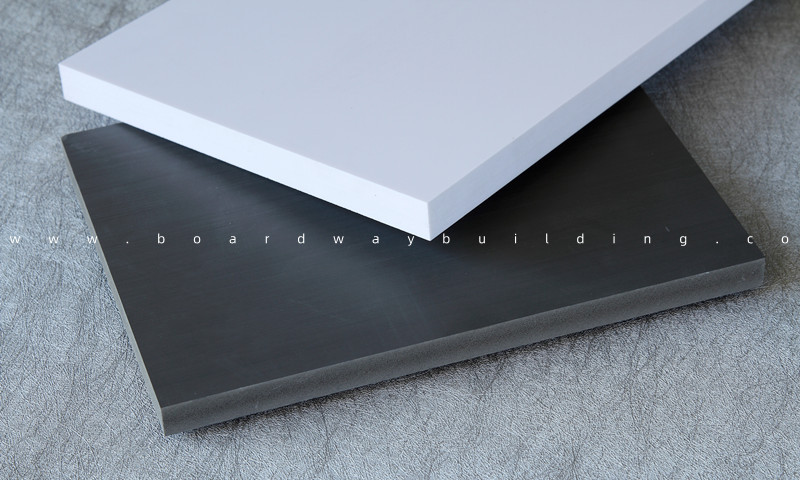

Both PVC foam board and WPC foam board are suitable as substrates, and the ideal thickness ranges from 5mm to 30mm. They can be used directly for lamination, or they can be surface sanded before lamination for a better fit.

Glue

The glue used for lamination is a fixed glue at room temperature, called PUR glue. It is melted into a liquid gel after being heated at high temperature, so that the glue can evenly cover the surface of the substrate.

Decorative Surface Material

There are many options for decorative surface materials, the most common are PVC film, high pressure laminate (HPL), aluminum sheet, in addition to acrylic sheet, PET sheet, and even glass can also be attached to the PVC foam board.

PVC foam board + PVC Film Laminates

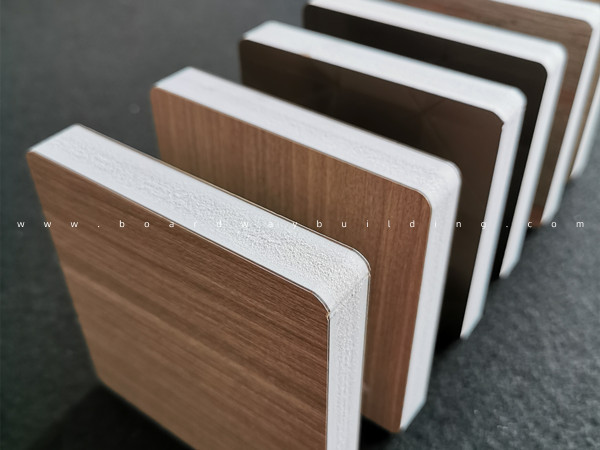

PVC film has become the most popular surface decoration material with the advantages of various colors, affordable price and convenient processing. It is not only suitable for laminating PVC foam board, but also a common decorative surface material for laminating wood boards and profiles such as MDF and particle board.

Common thicknesses of PVC films used for lamination range from 0.15mm to 0.25mm. It comes in a variety of surface types, including matte, glossy, and textured. There are several series of patterns, of which the wood grain series and the marble series have the most diverse styles, especially suitable for furniture and wall panels.

PVC foam board + HPL Laminates

HPL stands for High Pressure Laminate, also known as Phenolic Laminate. Unlike PVC film which is in rolls, HPL is in sheets. It is made of multiple layers of kraft paper impregnated with phenolic resin, and then pressed under high temperature and high pressure.

The thickness of HPL used for lamination is generally 0.7mm and 0.8mm. It is a bit more expensive than PVC film, but with it comes better scratch resistance and flame resistance. HPL also has a variety of surface types and patterns to choose from, which can basically meet the decoration needs of various styles.

PVC foam board + Aluminum Sheet Laminates

Furniture with aluminum sheets has become more and more popular among Chinese consumers in recent years. A big reason is its high safety. Compared with HPL, aluminum sheet has higher fire resistance and environmental protection performance. The PVC foam board laminate with aluminum sheet has strong heat resistance and can withstand the temperature of 300 degrees Celsius without being damaged.

Aluminium commonly used for lamination are sheets with a thickness between 0.2mm and 0.3mm. The thickness of the aluminum in rolls is about 0.17mm, and it is often used for the back lamination of PVC foam board to ensure the strength of the board is balanced without bending.

PVC foam board + Acrylic Laminates

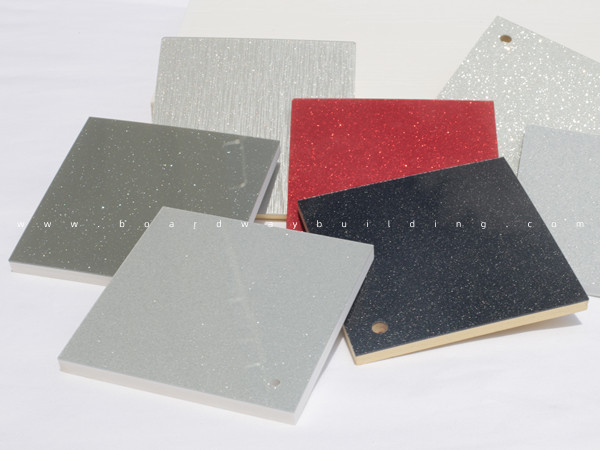

Acrylic sheet as a laminated surface material is actually a composite material of transparent acrylic and PVC film. You may be wondering, why not just use high-gloss PVC film, but add a thin transparent acrylic sheet?

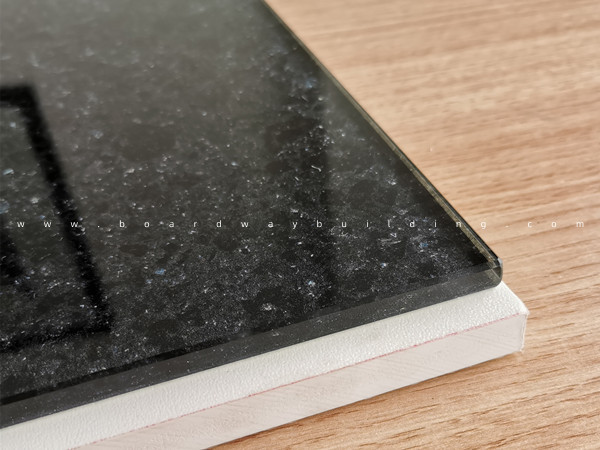

Using acrylic as the surface material of PVC foam board, its gloss is unmatched by other surface materials. In addition, it makes up for the disadvantage of high-gloss PVC film that is not scratch-resistant. In particular, the sparkling style PVC foam board laminate shown in the image below is a single-sided acrylic sheet with a thickness of 0.9mm laminated on a PVC foam board with a thickness of 8mm. Our customers apply this PVC foam board laminate to the wall of the shower room, which is very suitable for stylish decoration.

PVC foam board + Glass Laminates

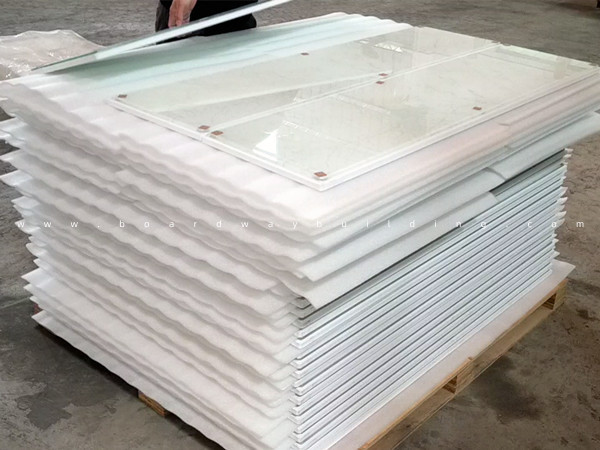

In addition to those thin decorative surface materials just mentioned, even glass can be laminated on PVC foam sheets.

Glass suitable for lamination has a thicker thickness and is relatively hard, and can be laminated on one side. Glass laminated PVC foam board has very significant advantages, such as waterproof and mildew proof, stain resistance, easy to clean, durable, and elegant appearance, suitable for kitchen cabinets. Speaking of its shortcomings, perhaps only the high price.

Processing Services

Cut to size and CNC cutting

Pre-drilled, slotted, rounded corners and edges, etc

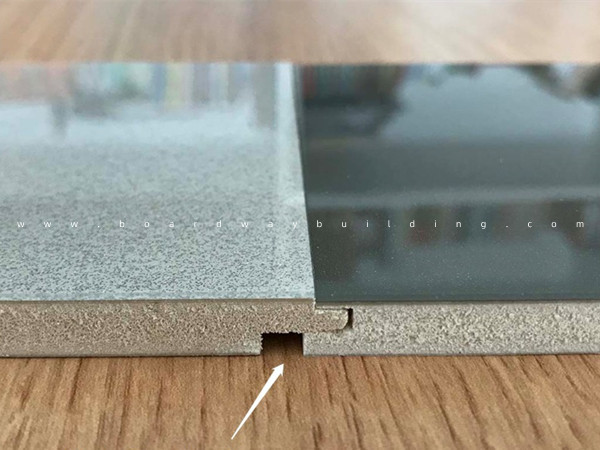

Grooved and tongued

Provide PVC edge banding close to the decorative surface and edge banding processing

Purchase Notes for PVC foam board laminates

Minimum Order Quantity

We have commonly used decorative surface materials in stock, if they can meet your needs, we will not have MOQ requirements. To order decorative surface materials, their minimum order quantities are as follows.

PVC film (in roll): 2000 meters

HPL and acrylic (in sheet): 100 pieces

Aluminum sheet (in sheet): 1500 pieces

Glass: contact us to get the MOQ

Installation Method

For customers who buy PVC foam board laminate for the first time, please tell us how you use it and your installation method, which will determine whether the decorative surface material is laminated on one side or two sides. Single-sided laminates are unbalanced in strength. In the absence of external force, the board will gradually become warped. Single-sided laminate is only feasible when the installation method is attached to the wall or fixed with a frame. PVC foam board laminate for furniture, we strongly recommend you to use double-sided laminate.

Thickness Tolerance

If there are strict requirements on the thickness of PVC foam board laminates, please be sure to inform us of the acceptable thickness range in advance. We will control the thickness of PVC foam board in the production stage.

Processing Fees

Please feel free to for lamination processing fees. The PVC foam board laminated with high-gloss PVC film can easily see the impurities on the board surface, which increases its processing difficulty. We must strictly control the particulate matter and dust in the workshop to avoid falling into the middle of the laminate. Therefore, its processing fee is relatively high.

Last but not least, the decorative surface material must be opaque, we believe you do not want to see the glue and substrate under the surface material.

Click to view Boardway Product List

Click to view Boardway Processing Services