What Are the Packaging Methods of PVC Foam Board?

To ensure that the PVC foam boards received by our foreign customers are qualified and still in good condition, Boardway has done everything possible.

Before production, we strictly control the source and quality of raw materials. In production, we have QC to monitor product quality from all aspects. Of course, we also take the packing of the goods seriously and protect them fully. No matter how good the quality of the product is, if it is damaged due to improper packaging during shipping, it is also unqualified. So we say that packaging is also a very important part of the product.

What packaging materials will be used for packaging PVC foam board?

According to the role these packaging materials play in packaging, we classify them into two types: main packaging materials and auxiliary packaging materials.

The main packaging material can be directly used for packaging PVC sheets. The auxiliary packaging material is used to package the PVC sheet with the main packaging material, and it cannot be used to pack the PVC sheet independently. The relationship between the two is complementary.

Main packaging materials

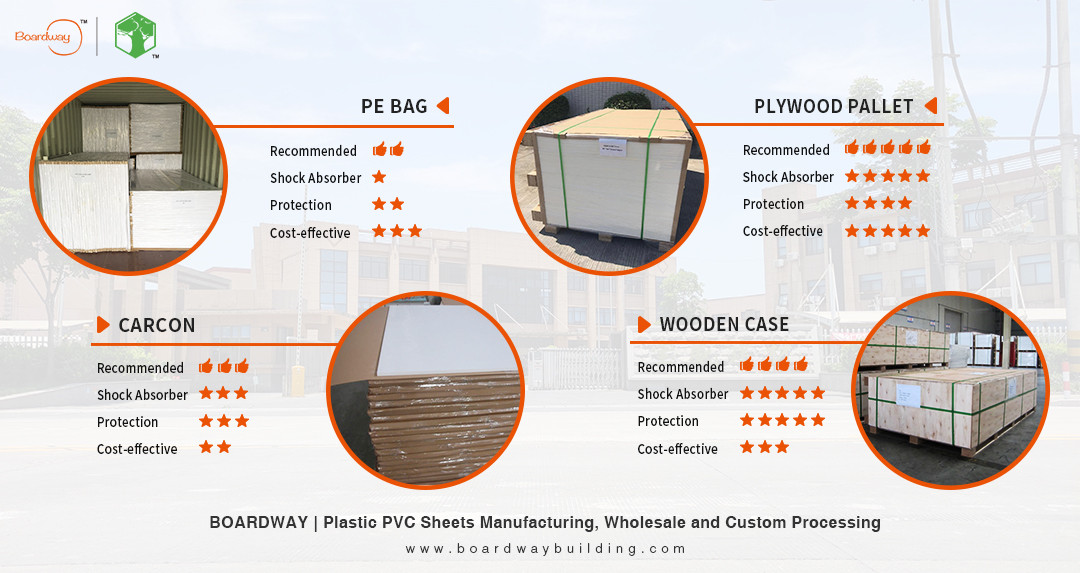

PE bag, carton, plywood pallet, wooden case, metal pallet

Auxiliary packaging materials

protective film, stretch film, cardboard corner protector, PP packing strap, EPE foam, protective plate, kraft paper

We combine the main packaging materials and auxiliary packaging materials into different packaging methods for PVC foam board. Let's take a look at what packaging methods are available and how effective they are in protecting PVC sheets.

What are the packaging methods of PVC foam board?

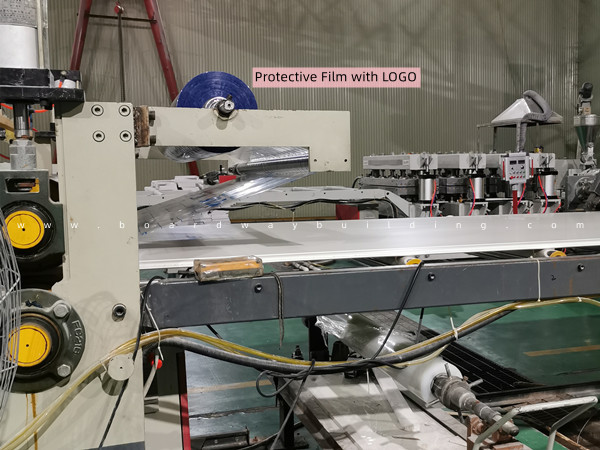

Protective Film

Recommended: ☻☻☻☻☻

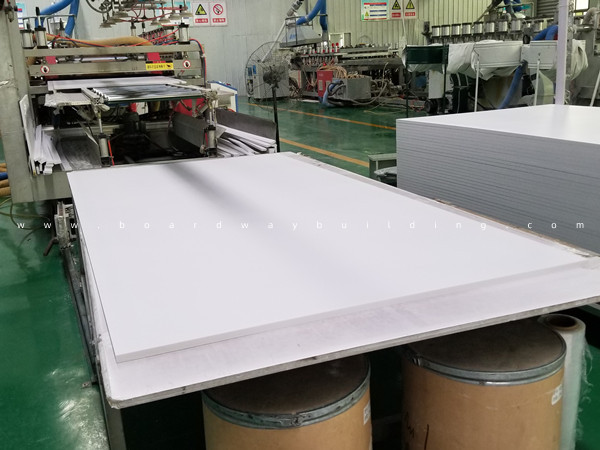

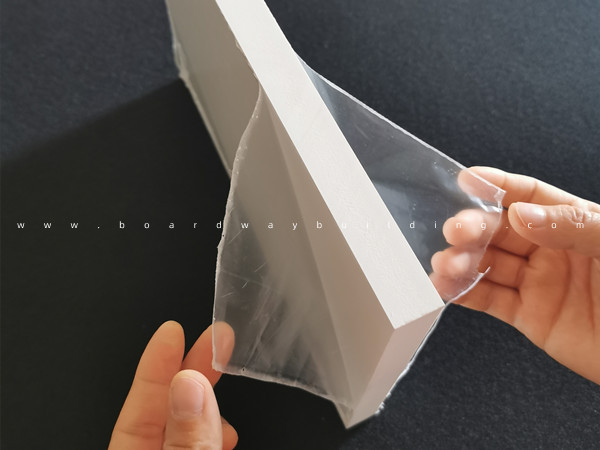

Before sharing the packaging method of PVC foam board, we would like to introduce the protective film first. The protective film is a thin PE film attached to the board surface during the production process of the PVC foam board.

Protective film is the most effective packaging material to protect the board surface from scratches or dirt. Especially when the PVC foam board needs to be cut or used for printing, we strongly recommend covering the PVC foam board with a protective film.

Protective film is not standard for our PVC foam board, we let our customers to decide not to use, single-sided, or double-sided protective film according to their own needs. Our factory provides neutral protective film, including transparent film and blue transparent film. Customers can also customize the protective film with the company logo, which can not only effectively protect the board surface, but also promote the brand recognition in the local market.

The protective film is aimed at the surface protection of the PVC foam board, but cannot protect the safety of the entire board. The packaging method we will share below is to protect the board from damage caused by shock or collision during transportation. For standard size PVC foam board (4x8 ft), we comprehensively analyze and compare these packaging methods from the three factors of shock absorption, protection and cost-effective.

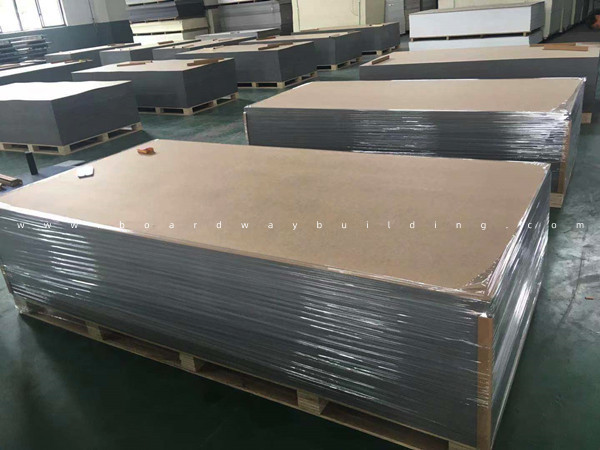

① PE Bag + Cardboard Corner Protector

Recommended: ☻☻

Shock Absorber: ★

Protection: ★★

Cost-effective: ★★★

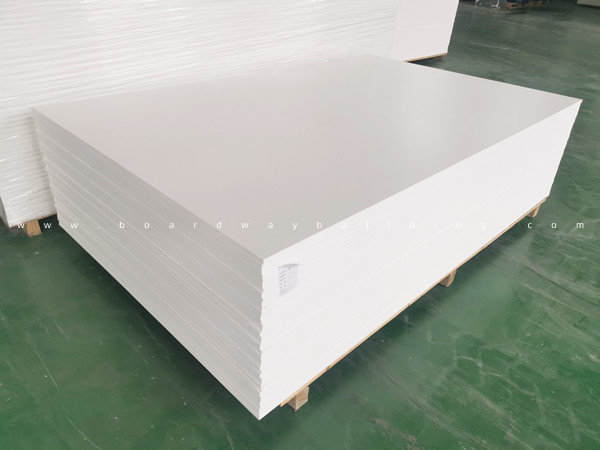

Pack several sheets of PVC foam board with PE bag. Usually the weight of a pack does not exceed 55KG.

PE bag is the packaging material that takes up the smallest container space, and it is also the cheapest. Many of our customers want to pack as many PVC foam boards into 20ft containers as possible, so PE bags are the most suitable packaging method. The weakest part of the PVC foam board is its four corners, and the paper corner protectors are placed at the four corners for protection.

However, when PE bags are used for packaging, the loading and unloading of PVC foam boards requires manual lifting, and it is unable to use forklifts, which leads to higher labor costs. In addition, the PE bag has no supporting force, so it may not be possible to avoid the bending or deformation of the PVC foam board caused by the improper loading of the board.

② Carton

Recommended: ☻☻☻

Shock Absorber: ★★★

Protection: ★★★

Cost-effective: ★★

Pack several sheets of PVC foam board in a carton. Usually the weight of a carton does not exceed 55KG.

The carton packaging method is very similar to the PE bag, but it provides safer protection for the PVC foam board. It can resist light bumps to the board.

However, the reason why we think carton packaging is not so cost-effective is because it does not provide the best protection for PVC foam board during shipping, but it is the most expensive packaging material. Nevertheless, carton packaging is still a very popular packaging method for most customers. Because it works for both distributor type and retailer type customers. A carton packs a certain number of PVC foam boards, making it easy to store, sell and distribute.

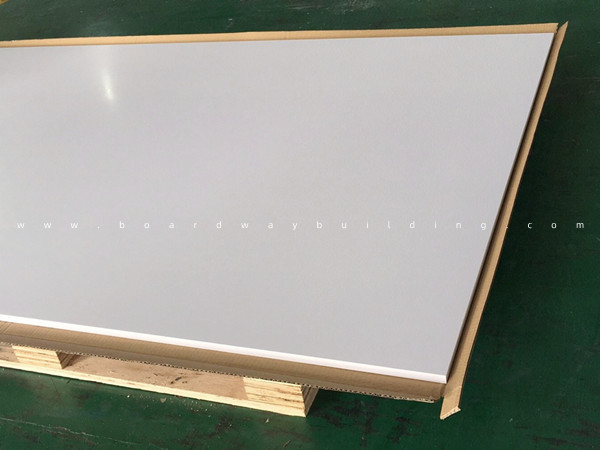

③ Plywood Pallet + Stretch Film + Cardboard Corner Protector + PP Packing Strap + Protective Plate

Recommended: ☻☻☻☻☻

Shock Absorber: ★★★★★

Protection: ★★★★

Cost-effective: ★★★★★

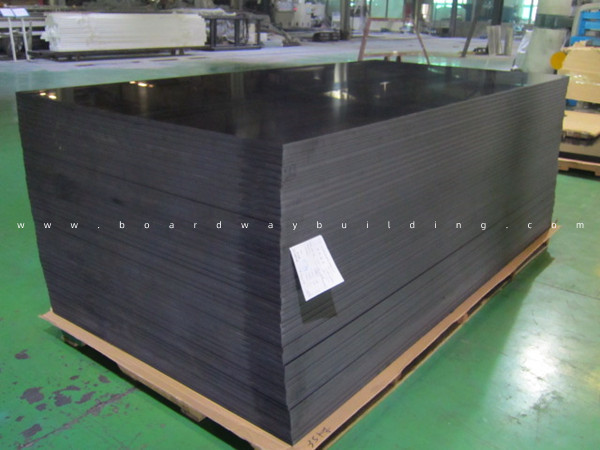

Stack PVC foam boards on plywood pallets, add paper corner protectors and protective plate, wrap it with stretch film, and then use PP packing strap to reinforce the whole pallet.

This is our most recommended and most commonly used packaging method. It gives the PVC foam board enough protection during shipping, and can effectively prevent the board from bending due to vertical loading. What's more, it can be loaded and unloaded by forklift, which is convenient and fast. Still, it couldn't withstand the surrounding bumps from the whole pallet.

If we also want the PVC foam board to be convenient for sale and distribution, we can combine cartons and pallets for packaging. This also strengthens the protection of the PVC foam board.

④ Wooden Case + PP Packing Strap

Recommended: ☻☻☻☻

Shock Absorber: ★★★★★

Protection: ★★★★★

Cost-effective: ★★★

Needless to say, wooden case provides the highest protection for PVC foam boards. Even if the wooden case is subjected to a large impact, or the goods encounter large shake during transportation, it may not cause damage to the PVC sheet.

However, the cost of the wooden case is high, and it has a rather heavy weight, which increases the transportation cost of the goods. If you want to maximize the protection of the board, and you have a sufficient budget, this packaging method is optional.

Which packaging method is most suitable for PVC foam board?

Based on our more than 10 years of experience in exporting plastic PVC sheets, we have found these most suitable packaging methods for PVC foam boards.

We do not advocate excessive packaging.

Excessive packaging increases the cost of packaging materials and transportation costs, and is also a waste of packaging materials. Choosing the most suitable packaging material with good protection is the best packaging method for PVC foam board.

All packaging materials we supply to our customers are brand new. Packaging materials made of wood, such as cartons and plywood pallets, are not disposable. We strongly recommend that our customers recycle and reuse them.