Common Misconceptions About Porcelain Slabs

If you don't know what a porcelain slab is? Take a quick look at the blog we share: Sintered Stone Make Quality Life

As porcelain slabs become more and more well known to the public in recent years, they are favored by furniture designers and decoration designers for their advantages of superhardness, scratch resistance, high machinability, food contact, easy cleaning, and durability.

We can even say that the more you know about the porcelain slab, the more you will like it.

However, there are still many users who may hesitate in the face of porcelain slabs when making decoration plans or purchasing furniture. They may have heard the evaluation of the porcelain slab:

"Porcelain slabs are fragile."

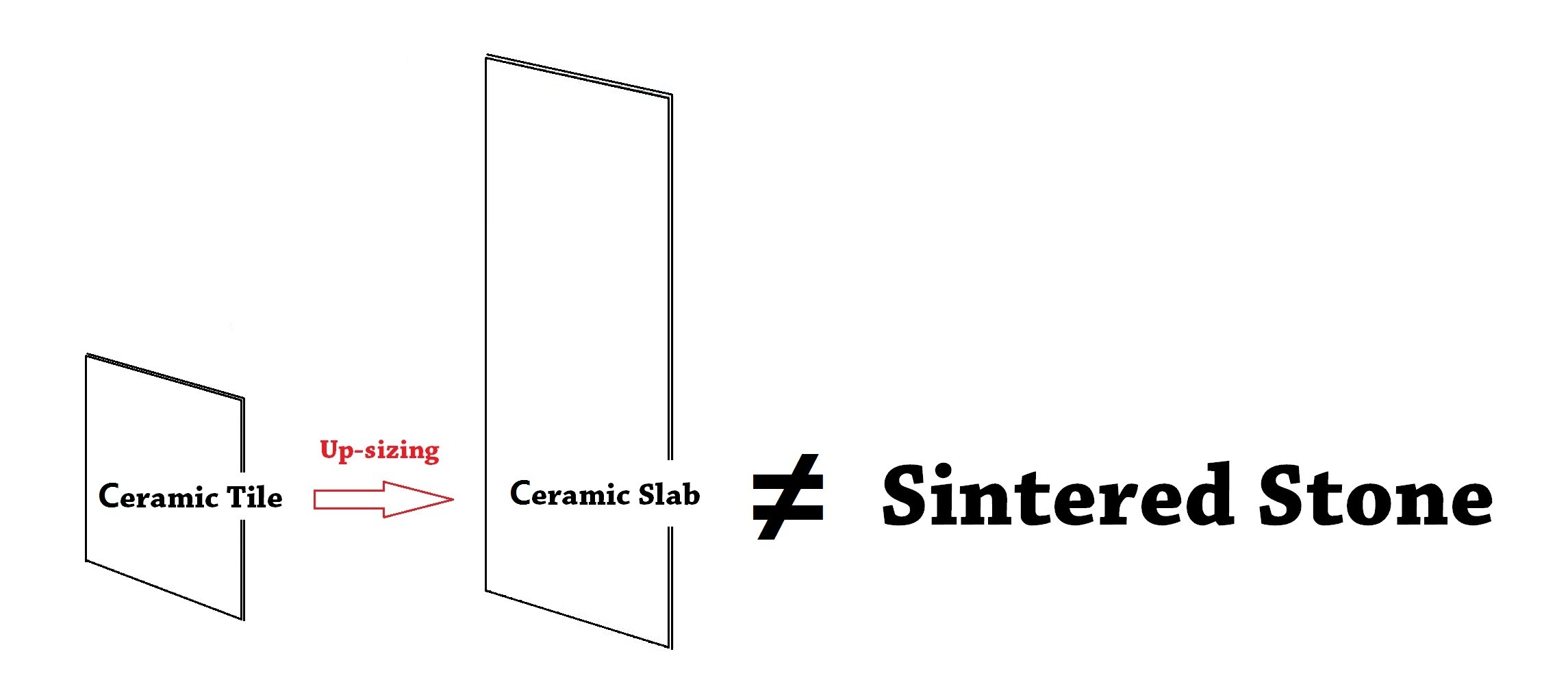

"Porcelain slabs are ceramic tiles with a bigger size."

"The stains can seep into the porcelain slabs and cannot be cleaned."

These are actually misconceptions caused by not understanding the porcelain slabs. In this blog, let's clarify for porcelain slabs.

Traditional ceramic tiles are mostly 300x300mm, 300x600mm, 600x600mm, 800x800mm, and 200x1200mm in size. But with changes in decoration design and preferences, ceramic tiles have introduced larger sizes to match more application needs, such as 600x1200mm, 750x1500mm, 900x1800mm sizes.

For non-professionals, it is really difficult to distinguish porcelain slabs from ceramic tiles in appearance. But in fact, there are big differences between the two in terms of raw materials, properties, processing, and applications. Porcelain slabs have extremely low water absorption, much lower than ceramic tiles. Porcelain slabs can be cut to any size, edge and corner finish, and are suitable for use on countertops, table tops, cabinet doors, and wall decoration.

As a porcelain product, porcelain slabs have a very high hardness. High hardness may indicate that it is brittle, but not fragile. Porcelain slabs have certain ductility and are suitable for deep processing, and can be easily drilled, cut, and polished. Even a 3mm porcelain slab has a certain toughness and can naturally bend to a certain arc.

Porcelain slabs and their products must be adequately protected during processing and transportation so as not to break.

Will the surface of a porcelain slab become discolored compared to solid surfaces like granite and quartz? Especially white ones?

In fact, on the contrary, the surface of the porcelain slab does not change color. The texture and color of the porcelain slabs are 3D printed, then glazed and fired. This manufacturing process mimics the natural texture of stone. Porcelain slab has a higher density than granite and quartz stone, so it is less likely to absorb moisture and will not be penetrated by other components.

We are very confident that the surface of the porcelain slab will not change color, nor will it fade due to long-term use. Of course, to have such quality, the technical requirements are very high. Some porcelain slab manufacturers do not have such technology, which is the difference between high-end porcelain slabs and low-end porcelain slabs.

The commonly used thickness of porcelain slabs are 3mm, 6mm and 12mm. There are also ultra-thick porcelain slabs with a thickness of 20mm. For use as a countertop, a porcelain slab with a thickness of 12mm is completely sufficient. If you want to have a thick countertop, we would recommend a 20mm thick porcelain slab or make a hanging edge for the countertop.

Porcelain slabs have high density. In addition, it has undergone three glazing and ultra-high temperature sintering processes, so it will not be penetrated. Rather, it is easier to maintain. Most of the time in daily use, we only need to clean the surface with a damp cloth. Difficult-to-clean stains can be easily removed with a cleaner. Porcelain slabs are resistant to organic and inorganic solvents, disinfectants and cleaning agents. It maintains its performance after heavy use and frequent cleaning.

Sintered stone has large size, its cutting and processing requirements are higher. Only with professional processing technology can achieve the processing and application of sintered stone. Inappropriate processing equipment and inadequate processing technique will cause waste to the materials, and even affect the quality of customized products.

Boardway has a wealth of experience in the processing of sintered stone. Our processing center has professional processing equipments and a well-trained processing team. OEM countertops are exported to Australia, the United States, Europe and other countries. If you would like to know more, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Center