What's So Good About PVC Foam Board?

If you ask me, "What is PVC foam board for?"

I will definitely answer you like this, "PVC foam board is multifunctional and it has a wide range of uses. PVC foam board is an ideal alternative for artificial wood panels, it is an excellent printable material for signs and displays, it is a waterproof building board used in interior furniture and decoration.”

If you are not familiar with PVC foam board, you may have such a question, why do people choose PVC foam board? What's so good about it? What benefits can we get from PVC foam board? So now, we will give you the answer in detail.

PVC foam board is moisture and mildew resistant.

The waterproofness of PVC foam board is not achieved by blocking moisture from entering the interior of the board like artificial wood boards. But because the foamed PVC sheet is a rigid closed-cell foam core plastic, which itself is a non-absorbent material. It can fully reflect its advantages in the application of kitchen cabinets and bathroom vanities. It can be used in any wet corner, or used in semi-outdoor areas such as balconies. PVC foam boards don't have the nutrients needed for mold to grow, so we won't see them. This greatly reduces our cleaning and maintenance costs.

PVC foam board is easy to handle.

PVC foam board can be very light, which makes it easier for us to carry it or handle it. Of course, this means that we can make it a very light weight under the premise of meeting its application requirements. How light is it? For example when it is compared to solid PVC sheets, we use their density to compare their weight. Under the same volume, the higher the density, the heavier the weight. The density of solid PVC sheet is between 1.35 and 1.45g/cm3, while the density of PVC foam board is between 0.45 and 0.6g/cm3. Obviously, the weight of the PVC foam sheet is only half or even one third of the solid PVC sheet. So, if you need solid plastic boards, but you want something lighter and easier to carry, consider PVC foam boards!

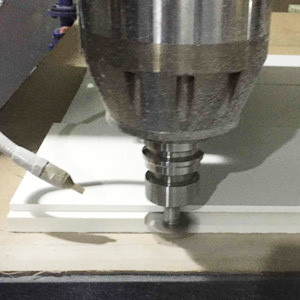

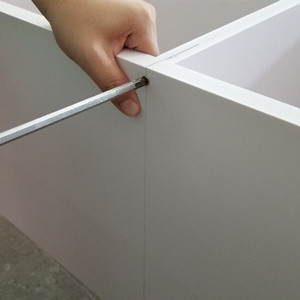

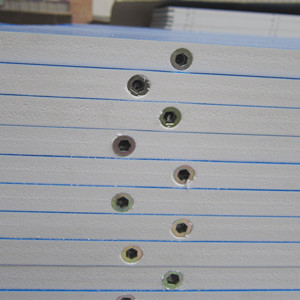

PVC foam board is easy to work.

PVC foam board has no tool requirements and restrictions for its use or processing. There are many ways to process it, sawing, CNC cutting, grooving, drilling, screwing, nailing, trimming, surface sanding, groove and tongue joining, edge banding, lamination, paint, hot bending. To carry out these processing, we can use those ordinary woodworking tools, and do not need any special tools or equipment. If you are a manufacturer of wooden furniture, no additional investment is required to process PVC foam board. The PVC foam board with laminated surface material is given a beautiful appearance, disguised as a wooden board, which makes you wonder, when did the wooden board become waterproof and maintenance-free?

PVC foam board is corrosion-resistant and self-extinguishing from fire.

The use environment of wood determines the service life of wood. One of the main reasons for shortening the working life of wooden building materials is decay. Moisture and microbes are the main contributors to decay, while termites eat wood, not to mention chemicals like acids and bases. This is why PVC foam board is popular because it is not easy to corrode, which means it is durable and can have a longer service life. Its combustion performance is self-extinguishing from fire, and it is one of the flame-retardant materials. If your application requires a higher fire rating, we can add flame retardants to its raw materials. Such PVC foam board can reach Class A of ASTM E84.

High-density PVC foam sheet has better impact resistance.

As mentioned above, if we want a lightweight PVC foam board, we can choose a density between 0.45 and 0.55g/cm3. What if we need a stronger PVC foam board with better impact resistance? The answer would be a PVC foam board with a density between 0.6 and 0.75g/cm3. The maximum density we can produce is 1.1g/cm3. Thanks to the controllable weight of the PVC foam board, it can be applied to a wider range of uses. In addition to densities that can be produced on demand, we can also tailor its properties to application needs. For example, the anti-ultraviolet-enhanced PVC foam board can be used outdoors and at sea, and the toughness-enhanced PVC foam board can be used in low temperature environments without being brittle.

PVC foam board is an excellent printing material.

There are many types of PVC foam boards, among which the PVC free foam board is made for printing. It has a matte surface that allows ink to adhere firmly. It has more size options, standard sizes are 1220x2440mm (48x96"), 1560x3050mm, 2050x3050mm. It is available in many colors, often produced in white, black, gray, red, yellow, blue and green, and the colors can be customized. Coupled with the durable performance of PVC foam board, it is an ideal material for medium and long-term indoor signs, and outdoor signs within a year are also competent.

So, if you ask me is PVC foam board worth more than artificial wood board? I'll tell you, "Yes! PVC foam board is more durable, looks better, requires no maintenance, saves you trouble and reduces costs."

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued