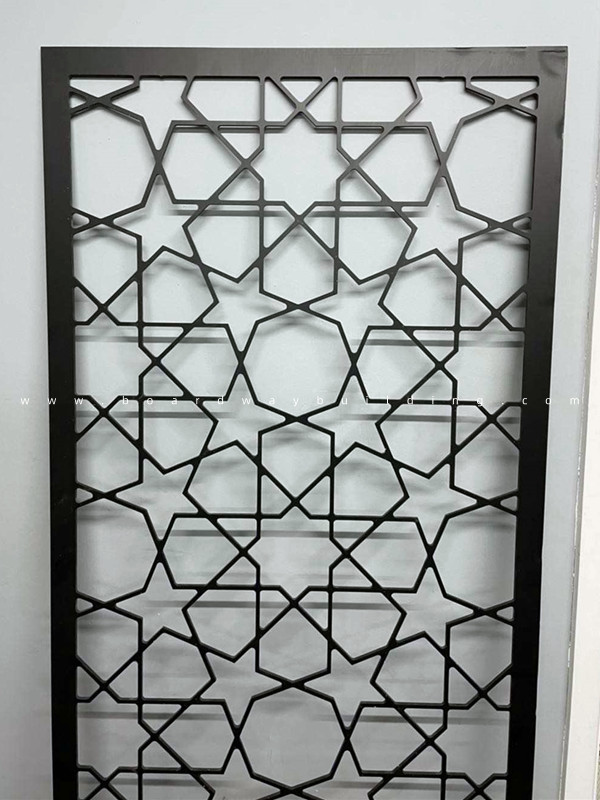

Openwork Panel Made of PVC Foam Boards

The term "openwork" generally refers to an ornamental design or decoration. Its most notable feature is its pattern of open spaces, or holes, created by cutting material from a solid object. This can be seen in various forms of art and architecture, such as intricate latticework, filigree or perforated metalwork. Essentially, openwork involves creating patterns of negative space within solid objects, resulting in visual impact and a refined appearance. When this solid object exists in the shape of a flat board, it is called an "openwork panel".

openwork panels can be made from a variety of materials, depending on the specific application and desired appearance. Some common materials used for openwork panels include wood, metal, stone, and even plastic or other composite materials.

In woodworking, openwork panels can be made by cutting intricate patterns into thin planks using a scroll saw. Metal openwork panels can be made through technical solutions such as metal casting, metal stamping or laser cutting. In stone carving, openwork designs can be achieved by removing material with chisels and other carving tools. Generally speaking, any material that can be shaped or cut in precise and intricate ways can be used to create openwork panels.

Versatility: PVC foam sheets can be easily cut and shaped to create intricate designs and patterns, making the job of making openwork panels easier.

Light weight: PVC foam board is light in weight, easy to handle and install. It's definitely a popular choice if the app tends to focus on weight.

Durability: Highly resistant to moisture, chemicals, and UV radiation, PVC foam board is a durable material that can withstand harsh environmental conditions.

Cost-effective: PVC foam board is an affordable material that will make your project cost-effective as compared to other types of materials.

How to install the openwork panel made of PVC foam board?

For example, as shown in the picture above, my customer has adopted two installation methods. The picture on the left is to fix the four edges of the openwork panel in the wooden frame to ensure that the whole board is flat and not bent. The picture on the right is to apply a generous amount of adhesive on the back of the openwork panel and press it firmly to the wall, then use the appropriate hardware to fasten the panel to the pre-drilled holes in the wall.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.