Why Is Measuring the Diagonals of PVC Foam Board Important?

Understanding the intricacies of PVC foam board and its measurement practices is crucial for making informed decisions about your projects. At Boardway, we take pride in sharing our expertise to help you achieve the best outcomes. In this article, we'll delve into why measuring the diagonals of PVC foam board matters, its significance in production quality, and its specific applications. Let's explore the world of PVC foam board measurement and its importance in ensuring precision and performance.

What is PVC Foam Board?

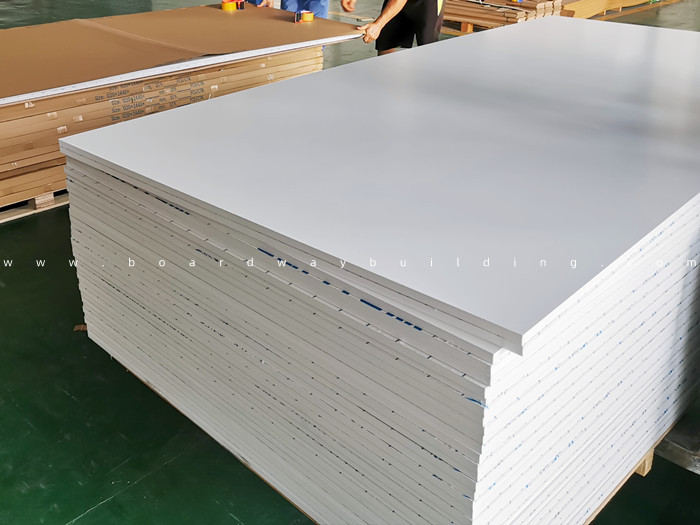

PVC foam board, also known as expanded PVC or foamex, has gained popularity across diverse industries due to its lightweight, durable, and customizable nature.

PVC foam board's versatility makes it a sought-after material in signage, construction, interior design, and beyond. Its cellular structure gives it strength while keeping it lightweight, ensuring ease of handling and installation. The material's ability to be easily cut, shaped, and printed upon makes it a staple in numerous projects.

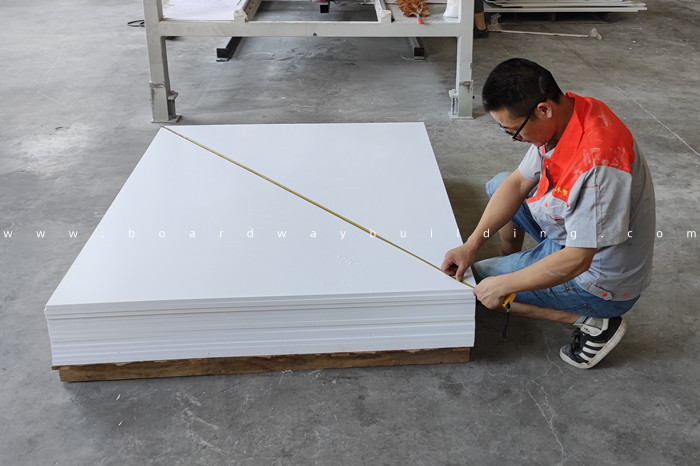

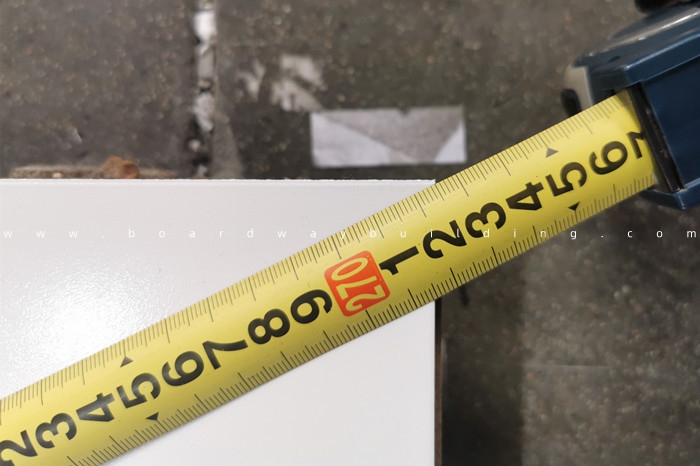

To ensure the highest standards, our production process involves stringent quality checks. Alongside measurements of length, width, thickness, surface hardness, and weight, we pay close attention to the diagonals. Measuring the diagonal of a PVC foam board is a common practice to ensure its dimensional accuracy and squareness.

The Significance of Diagonal Measurement

Cutting Small-Sized Panels

For projects requiring PVC foam board to be cut into multiple smaller panels, precise diagonal measurements are crucial. Even small deviations in diagonals could accumulate and result in irregularly sized pieces, impacting the final project's aesthetic and structural integrity.

- Inconsistent size: Large diagonal deviation indicates that the board is not perfectly square. When cutting the board into smaller pieces, the resulting boards may have inconsistent sizes and shapes. This can lead to difficulties in achieving uniformity and precision in the cut pieces.

- Misaligned edges: If the board is not square, the edges of the cut pieces may not be perfectly aligned. This can result in uneven or misaligned edges, affecting the overall appearance and fit of the final small-size boards.

- Difficulty in assembly or installation: If the small-size boards are intended for assembly or installation where precise dimensions are required, such as in construction or signage, the large diagonal deviation can cause challenges during the assembly process. It may be difficult to fit the misaligned pieces together properly or achieve the desired structural integrity.

- Wastage of material: When cutting a PVC foam board with a large diagonal deviation, there may be a higher level of material wastage. Achieving precise cuts and utilizing the maximum usable area of the board can be more challenging when the dimensions are not consistent.

Printing Applications

In the realm of printing, such as creating large-scale graphics or designs, accurate diagonals are vital. Misaligned diagonals can lead to uneven printing, distortion, or alignment issues, affecting the visual appeal and professional quality of the final output.

- Alignment and registration: If the PVC foam boards are not cut accurately or are not square, it may affect the alignment and registration of the printed design. Misaligned or skewed boards can result in misaligned prints or inconsistencies in the artwork across multiple boards.

- Mounting and framing: In some printing applications, PVC foam boards are mounted or framed to create a finished display. If the boards are not square or have inconsistent dimensions, it can make mounting or framing more challenging and may affect the overall aesthetics of the finished product.

- Overall presentation: While the impact may be more on the visual aspect rather than the printing itself, accurately measured and square PVC foam boards contribute to a more professional and polished presentation. A well-aligned and properly sized board enhances the overall visual appeal of the printed artwork or signage.

Measuring the diagonals of PVC foam board is not just a routine procedure but a critical step in upholding product quality and performance. At Boardway, we emphasize precision in all aspects of our production to ensure that our PVC foam boards meet the highest standards. As a leading manufacturer and supplier in China, we are dedicated to providing top-quality PVC foam board solutions that cater to your unique needs. Whether you're engaging in intricate cuts or demanding printing applications, trust Boardway to deliver products that excel. Reach out to us to learn more about our PVC foam board offerings and customizable solutions.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale@boardwaybuilding.com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.