Everything You Need to Know About WPC Foam Board

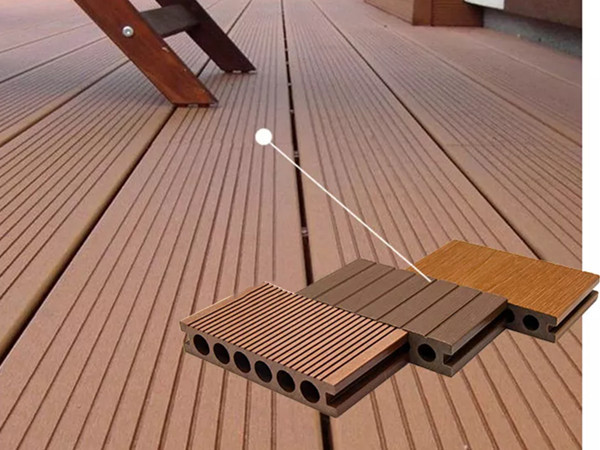

Is WPC foam board a WPC decking / WPC flooring?

Is WPC foam board a hollow fluted WPC wall cladding?

What exactly is WPC foam board? What is it for?

Have you ever had these questions when you saw the word "WPC foam board"? Anyway, we are often asked by our customers. Today, let's analyze what WPC foam board is and what is the difference between PVC foam board and WPC foam board.

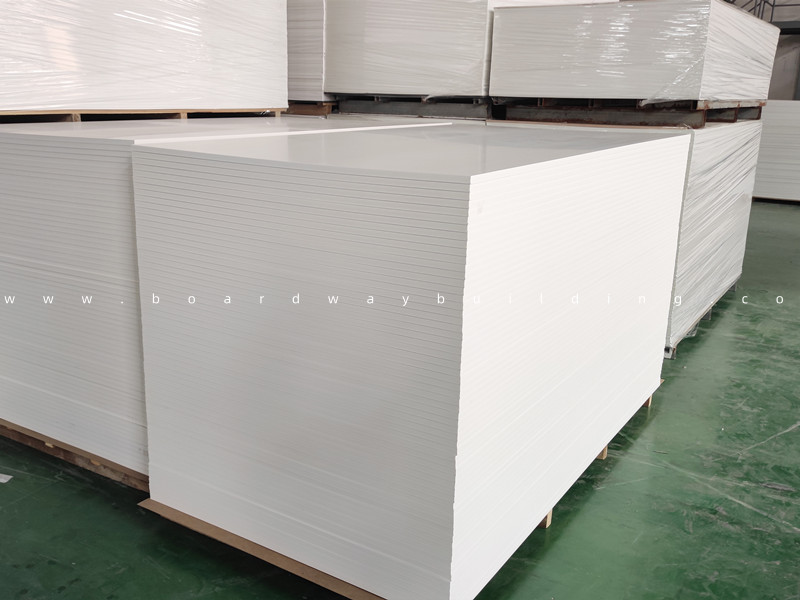

WPC foam board is one of the family members of PVC foam board.

WPC foam board is mainly composed of polyvinyl chloride (PVC), with a small amount of wood powder or bamboo powder, and auxiliary materials. It has the same manufacturing process as PVC foam board. The only difference from PVC foam board is that wood fiber is added to the raw material of WPC foam board.

Therefore, we often say that WPC foam board is produced on the basis of PVC foam board.

WPC Foam Board vs. WPC Decking vs. WPC Wall Cladding

Why people are confused by these products, because they all have the word "WPC". WPC stands for Wood Plastic Composite Panel. Precisely because they are so close in name, it is easy to make the mistake of thinking that they are just the same material with different uses.

But to us, a plastic sheet manufacturer, they are actually completely different products, they are made of different materials and used for different purposes.

|

WPC Foam Board

|

WPC Decking Wall Cladding for Outdoor

|

WPC Wall Cladding for Indoors

|

|

|

Composition

|

Mainly polyvinyl chloride (PVC), 5~10% wood powder

|

45~50% polyethylene (PE) and additives, 50~55% wood powder

|

30~35% polyvinyl chloride (PVC) and additives, 65~70% wood powder

|

|

Product Type

|

Sheets / Boards

|

Profiles

|

Profiles

|

|

Application

|

Wide range of applications, furniture, decoration and advertising, both indoor and outdoor

|

Outdoor flooring, pool decking, building facades

|

Decorative interior wall panels

|

Properties of WPC foam board

WPC foam board has the same properties as PVC foam board, such as light weight, moisture-proof and mildew-proof, insect-proof, non-flammable, formaldehyde-free, lead-free. What's more, it's easy to work and can be easily sawed, cut, drilled, screwed, nailed, sanded, laminated, painted, etc. WPC foam board is a perfect alternative to natural wood for building and decoration uses.

WPC foam board has the same specification as PVC foam board. We can produce widths of 915mm and 1220mm, thicknesses ranging from 5mm to 30mm, and density available from 0.4 to 0.9 g/cm3.

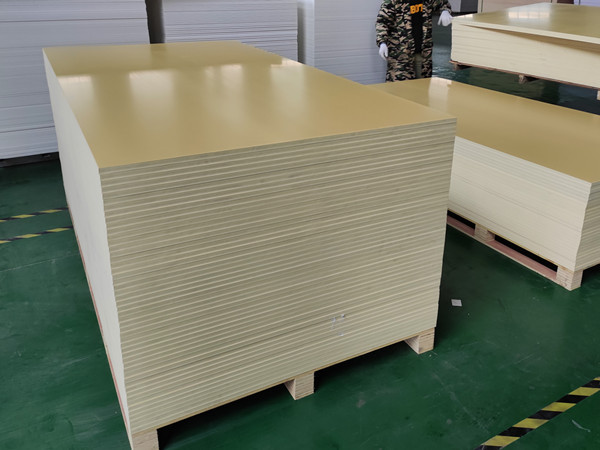

Generally speaking, color masterbatch is not added to the raw material of WPC foam board. Its yellow color is actually the color of natural wood fibers. Then, this may cause the color deviation in WPC foam boards produced from different batches of wood powder. But if we want to keep the color of WPC foam board consistent, we can only add color masterbatch to adjust the board color.

Since WPC foam board is so similar to PVC foam board, what advantages does WPC foam board have over PVC foam board?

Wood powder is definitely not added for nothing.

The decisive factor that affects the screw holding strength is the density. The higher the density, the stronger the screw holding strength. But increasing the density comes with an increase in the weight of the board.

How can we make the PVC foam board keep a lighter weight and have a better screw holding strength at the same time? Our solution is to add wood powder to the PVC foam board to increase the friction between the screw and the board, that is, to enhance the screw holding strength of the board.

Therefore, we can say that compared with the same specifications of PVC foam board and WPC foam board, WPC foam board has a better screw holding strength.

Does that mean that the more wood powder is added, the better screw holding strength we can get?

Of course not. Polyvinyl chloride resin can be expanded and foamed under the action of a foaming agent, while wood powder cannot.

As far as the manufacturing process of our factory is concerned, increasing the amount of wood powder can not reduce the weight of WPC foam board, and will affect the quality of foaming. The proportion of wood powder should be maintained within the range of 5% to 10%.

Click to view Boardway Product List

Click to view Boardway Processing Services